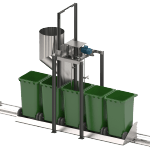

When it comes to waste management, balers are essential tools that help you manage recyclable materials efficiently. Whether you are considering the installation of a baler for the first time or looking to maintain an existing one, this guide will take you through the procedures and the necessary steps.

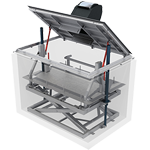

Installing Your Baler

Space Requirements

Before installing your baler, ensure you have enough space for its correct operation. The specific space requirements may vary depending on the type of baler you have, below you will find a general guideline:

DP Vertical Balers: These balers typically require a clear floor space of 2600x1400mm (for DP20) to 3000x1600mm (for DP25, DP30, DP40, DP50) and a ceiling height of up to 3200mm (for DP20) to 3400mm (for DP25, DP30, DP40, DP50). Keeping this space clear of any materials that could interfere with the baler’s operation is essential.

Positioning

Proper positioning of the baler is of extreme importance for safety and efficiency. Follow these positioning guidelines below:

The back of the baler should be placed at least 60cm from any structure to allow room for wire insertion and bale tying.

There should be enough room in front of the baler to allow the chamber door to fully swing open for the ejection of finished bales.

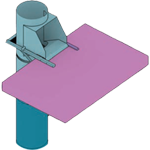

Anchoring

Securely fixing your baler is essential to prevent any instability during operation. It’s recommended to:

Mount the baler on a steel-reinforced concrete pad with a minimum capacity of 3000 psi.

Use at least four (or six for S865 Models) ¾” anchor bolts that are 5″ to 6″ long to fix the baler to the pad.

Electrical

Proper electrical installation is very important for the baler’s safe operation. Here are some key electrical considerations:

Install a lockable fused disconnect switch within 5 feet, in the line of sight of the baler’s electrical enclosure.

Ensure that the disconnect is appropriately sized according to the baler’s motor and voltage specifications.

Hydraulic

Inspect the hydraulic system for any oil leaks and ensure that all hoses are tightly secured.

Maintenance

Correct maintenance is vital to ensure your baler functions efficiently and safely. Here’s a maintenance checklist for your baler:

Daily Maintenance

– Inspect for oil leaks.

– Check the oil level (with the platen up, the hydraulic tank should be ¾ full).

– Inspect bolts, ejector chains, limit switches, welds, safety decals, guards, and the emergency stop switch.

– Remove any debris around and on top of the platen.

Monthly Maintenance

– Check for signs of wear, including scars on the cylinder rod, oil leaks, and door hinges/handwheel play.

– Lubricate moving parts (sprockets, chains, hinges, and turnbuckles) and replace or repair as necessary.

– Check hydraulic oil clarity; it should not appear cloudy or milky.

– Replace the air breather/filter if required.

– Replace the hydraulic oil filter located in the hydraulic tank under the access panel (replace every 12 months).

– Inspect hydraulic fittings and connections and make repairs or replacements as necessary.

Lockout/Tagout

Before performing any maintenance on the baler, it’s essential to follow the lockout/tagout procedure to ensure the equipment is isolated from all potentially hazardous energy. Always consult a qualified electrician to perform these procedures.

Emergency Operation

In case of an emergency while operating the baler, press the red stop button to shut down the machine.

Safety Precautions

It is of the utmost importance to follow these safety precautions:

- Never place hands or arms in the baler while it’s operating.

- Avoid standing behind the baler during operation.

- Do not climb on or in the baler unless the power is disconnected and locked out.

- Allow only qualified personnel to perform maintenance or repairs.

- Never disable safety switches.

- Avoid overloading the baling chamber.

- Do not place hazardous materials in the baler, including concrete, steel, explosives, liquids, or hazardous waste.

By following these installation and maintenance instruction, you can ensure the safe and efficient operation of your baler for recyclables, extending its lifespan and contributing to effective waste management.