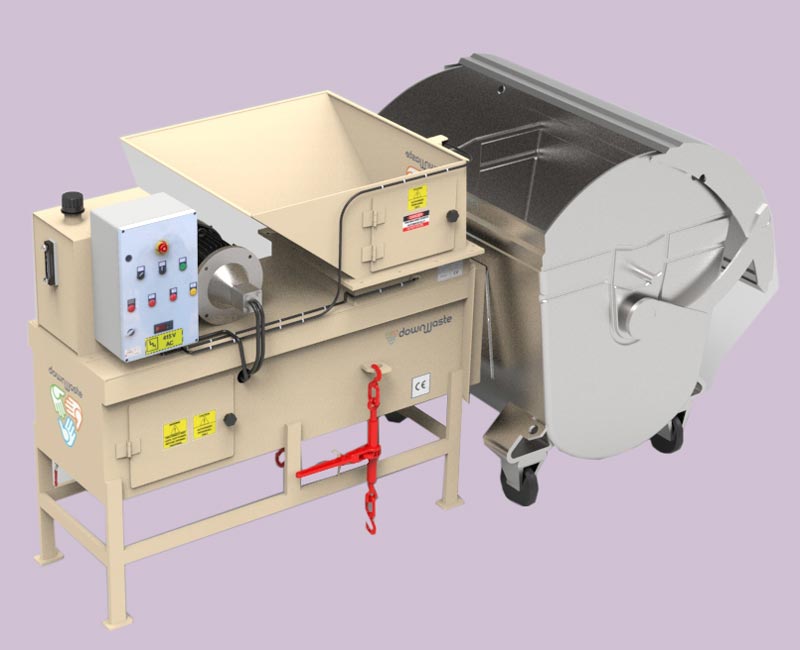

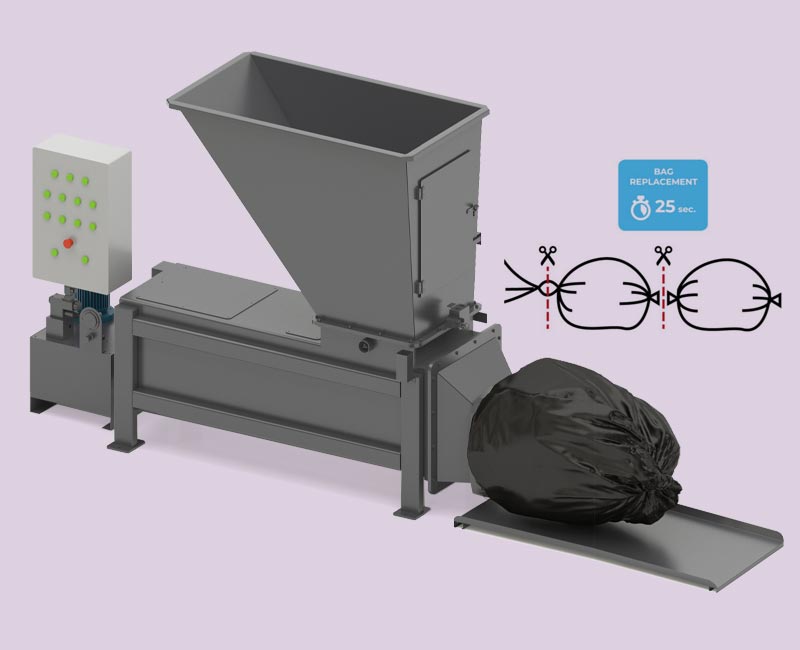

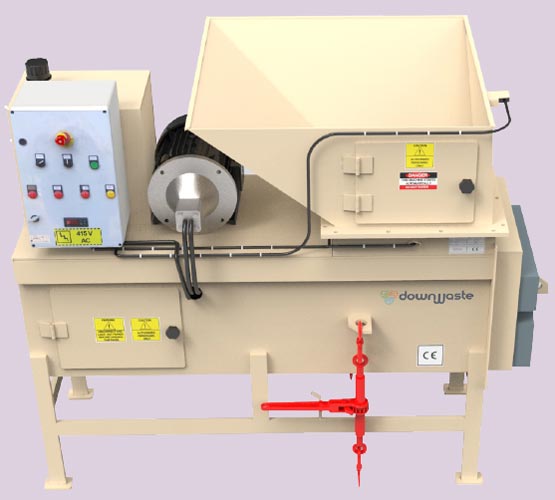

CHUTE FED COMPACTOR

DownWaste 10:1 – The Smart Waste Management Solution The Chute Fed Compactor is designed to enhance efficient waste management by compacting waste from an overhead chute in multi-story buildings. It significantly reduces bin replacement needs, making it the ideal choice for buildings with limited garbage room equipment space.