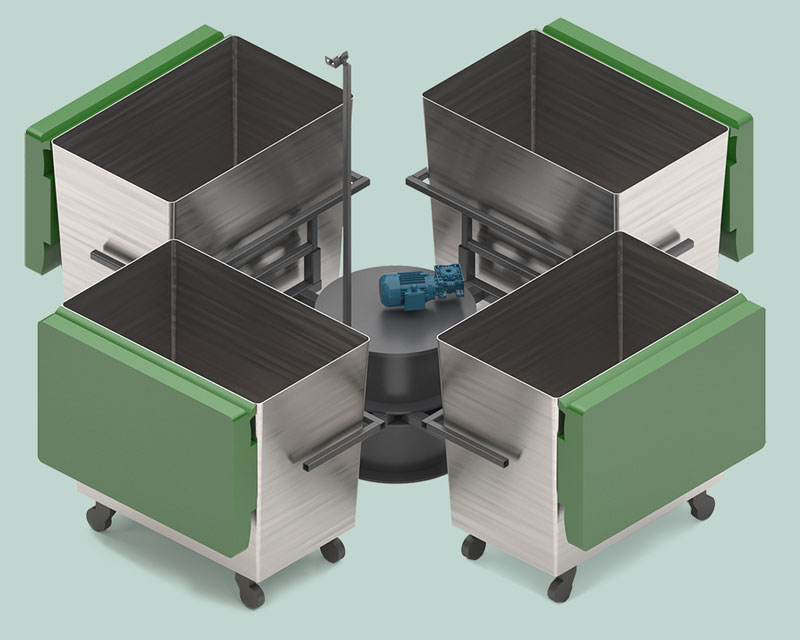

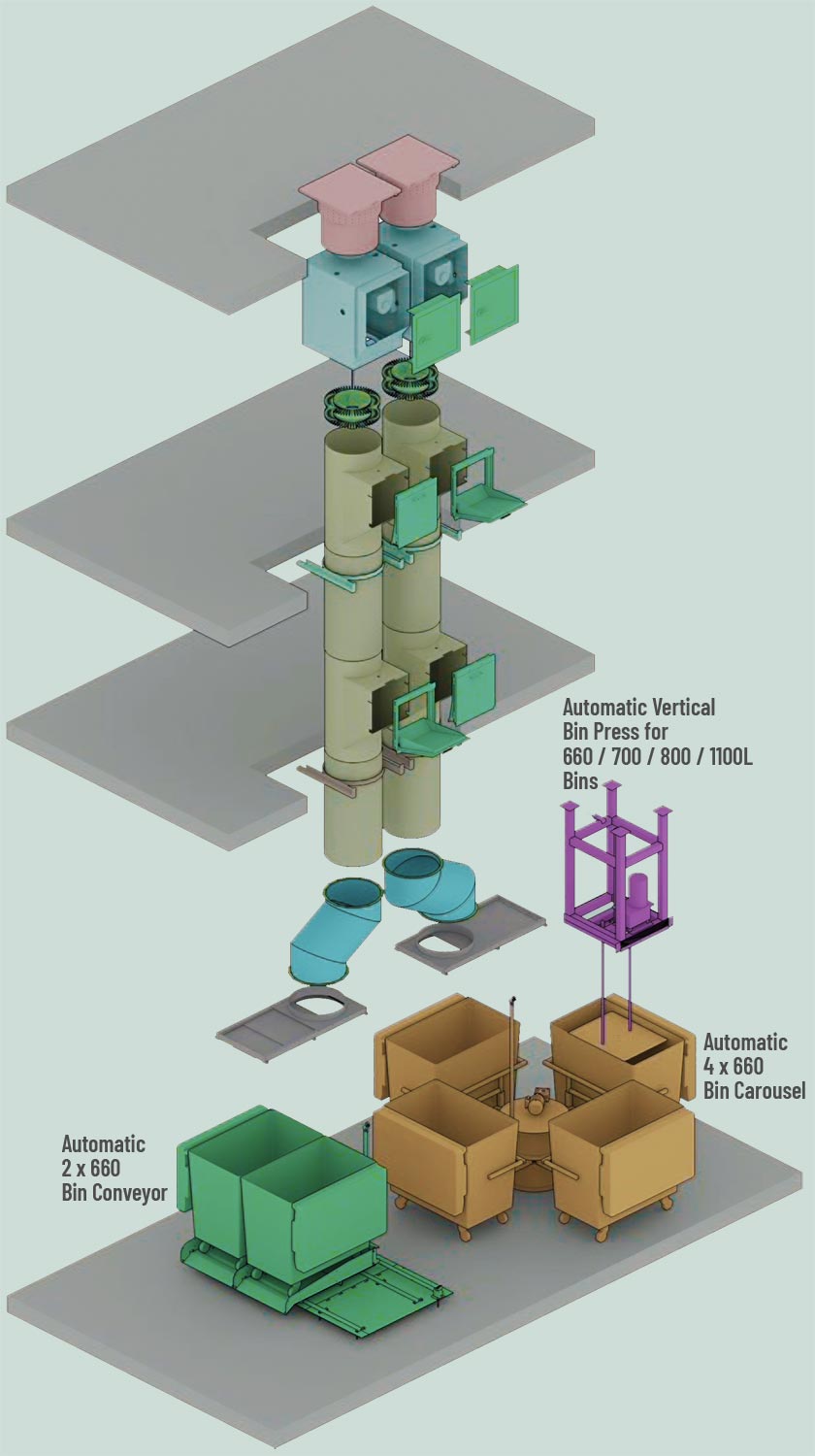

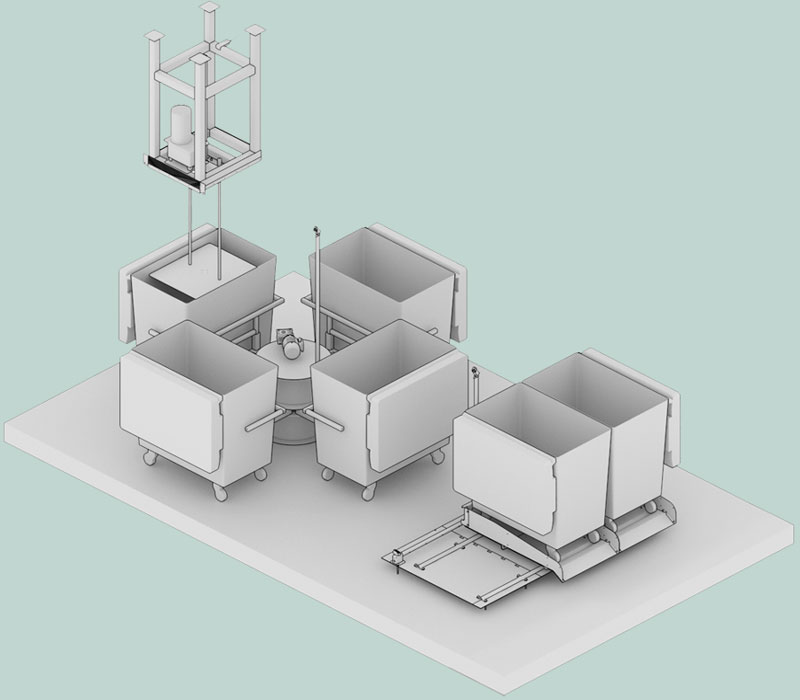

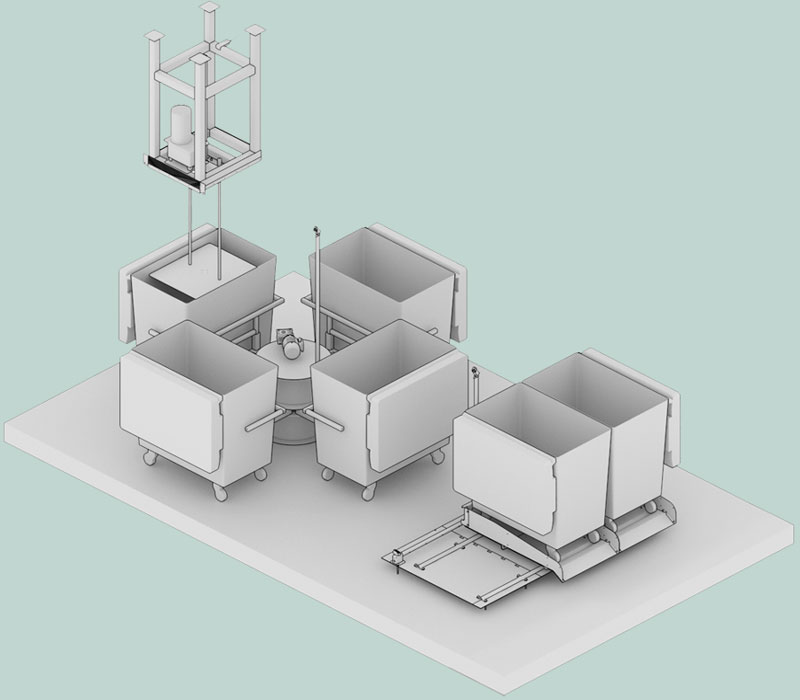

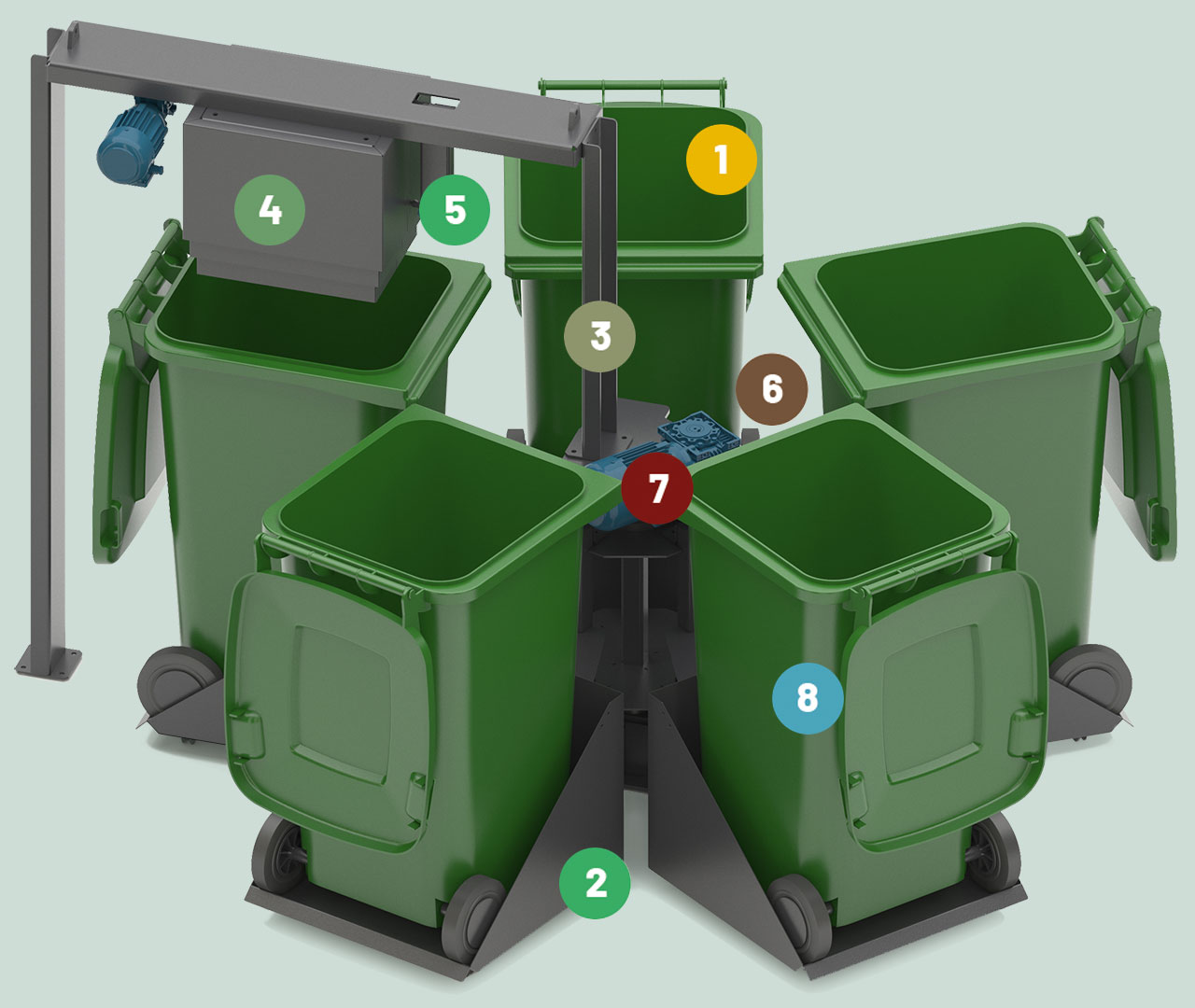

Bin Carousel

Embrace efficiency with our automatic carousels that dramatically reduce manual labor, streamline your waste handling process, and allow your staff to focus on more critical tasks. Invest in our technology to ensure a cleaner, safer, and more productive waste management operation. Situated directly beneath the chute discharge, our bin carousels feature advanced photoelectric proximity sensors and are powered by an electric motor coupled with a precision rack and pinion system. These systems are ingeniously crafted to seamlessly and quietly transition full bins with empty ones, ensuring a smooth and efficient automatic replacement process.

STRUCTURE

This system is designed to be completely safe, quiet, and efficient. It can be used in any existing building that has available space in the waste room.

INCREASED PRODUCTIVITY

Less time spent on the changing trolleys and monitoring the bins, more time for the staff to concentrate on other activities.

WHISPER, WHISPER

We designed a quiet and sophisticated system to manage your waste automatically. The bin feed is isolated with rubber pads and works silently.

SAFETY FIRST

The system is engineered for ultimate safety and simplicity. All moving parts are completely closed to prevent any hazards.

The vertical press cycles automatically with proximity sensors when the receptive bin is full, maximizing the eciency. The Bin and Press system is automated ingeniously to prevent any hazards and it automatically locks all the chute doors during compaction or moving the bins.

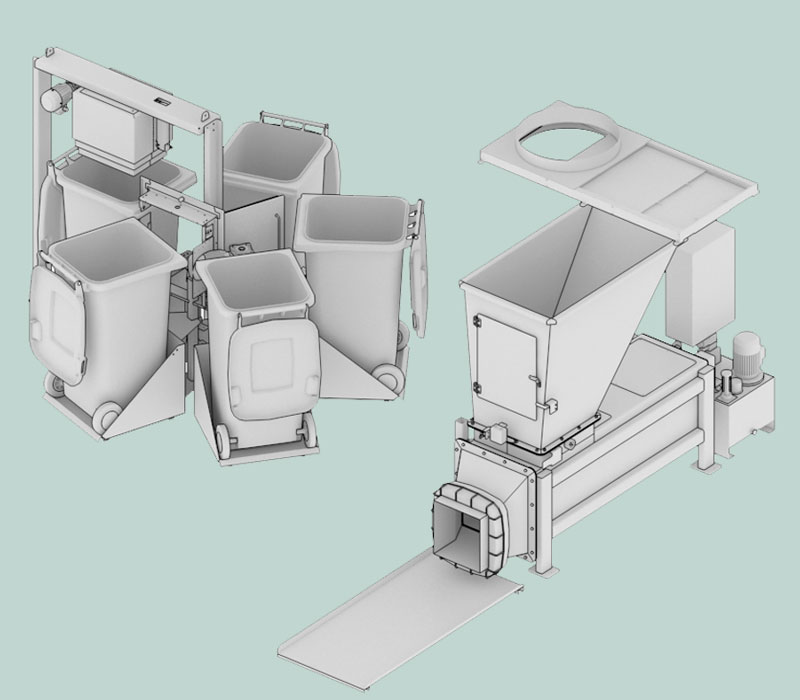

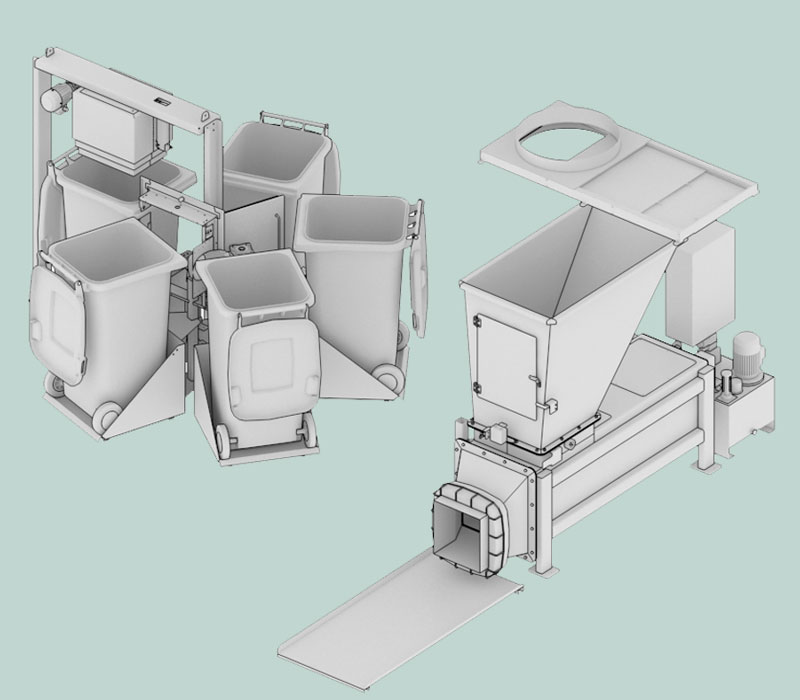

For the existing manual chutes, the bin press is equipped with a guillotine plate that closes the chute discharge during to compaction, preventing the falling objects from damaging the unit during its operation.

OPTIONS

- 2, 3, 4 or 5 bins carrier platform

- Integrated bin press for efficiency

- 240L / 360L / 660L / 1100L Bin Feeders

FEATURES

- Convenient loading and unloading of the bins

- Automatic and simple operation

- Cycle complete alarm

- Safe and reliable Siemens PLC control

- Sensors to automatically start the compacting process when the receptive bin is full

- Sensors to automatically cycle empty bins

- Simple and robust mechanical design for ease of installation, operation and maintenance

TECHNICAL DATA

Chute Discharge

Skirting Board

Carousel

Bin Press

Bin Sensor

Position Switch

Electric Motor

Waste Bins

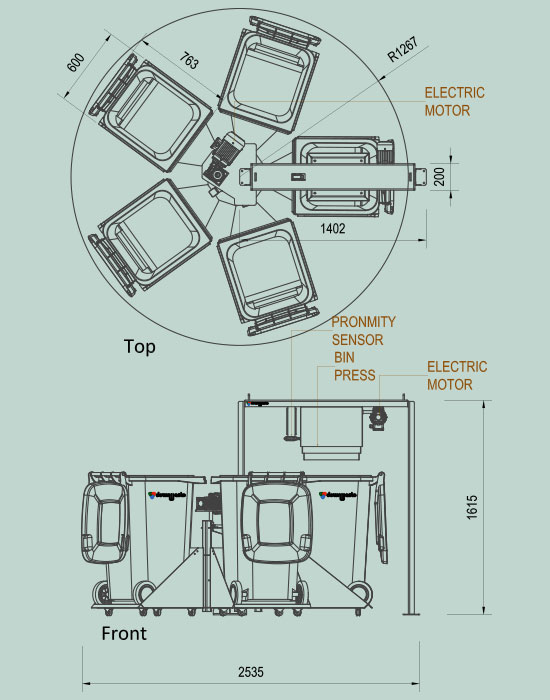

- RC.001

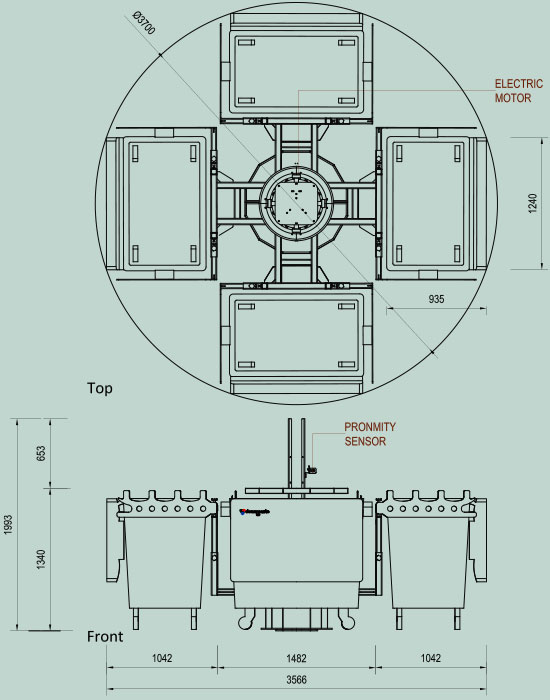

- RC.002

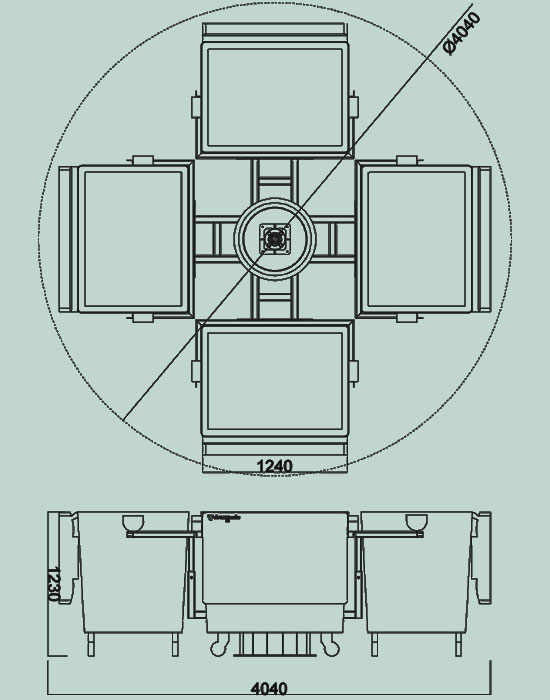

- RC.003

- Compatible BIN SIZES (L)240 L / 360L

- NUMBER OF BINS4 or 5

- Optional Vertical PressFloor/Ceiling Mount

- Machine Diameter2120 mm - 2560 mm

- Minimum Required Height2500 mm

- Power Supply380V

- Compatible BIN SIZES (L)660L

- NUMBER OF BINS2, 3 or 4

- Optional Vertical PressCeiling Mounted

- Machine Diameter3000mm / 3120mm / 3700mm

- Minimum Required Height2500 mm

- Power Supply380V

- Compatible BIN SIZES (L)1100L

- NUMBER OF BINS2, 3 or 4

- Optional Vertical PressCeiling Mounted

- Machine Diameter3300mm / 3560mm / 4040mm

- Minimum Required Height2500 mm

- Power Supply380V

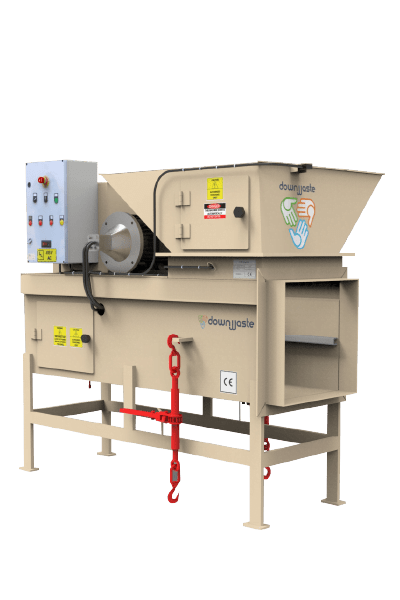

COMPACTORS

Hydraulic based chute fed

automatic compactors

BALERS

Vertical balers in various sizes

to produce bales from recyclables

PRESS COMPACTORS

Heavy duty waste press compactors for

residential and industrial mega buildings

HDPE BINS

HDPE wheelie collector bins

available in all industry sizes

GALVANIZED TROLLEYS

2500L and 1100L Heavy Duty

Hot Dip Galvanized Trolleys

PROLITEC ODOR CONTROL

Prolitec’s patented malodor

control technology

METAL WORKSHOP

Sorting tables for your indoor

recycling facility

The Trash Bin Feed & Press System is an automated solution for automatically managing chute fed waste bins, designed to cycle bins and compress waste, which saves space and reduces workload

Buildings with garbage chutes and high waste generation that require efficient management and space-saving solutions would benefit from this system.

It is important because it automates the waste management process, increasing productivity by reducing the time staff spend changing trolleys and monitoring bins

Benefits include increased productivity, less time spent on bin management, space-saving, and a reduction in the number of trolleys needed

Types are differentiated by bin size and the number of bins the garbage room can accommodate, with options for additional compaction features

The system automatically cycles and compresses waste bins wıth electrohydraulic motor and sensors. The feed mechanism is isolated with rubber pads to operate silently.

Main components include a motor, compression mechanism, rack and pinion trolley, rail, limit switches and electric control panel with necessary controls and indicators.

For a quote, you would need to contact the provider with your specific requirements and building detail.