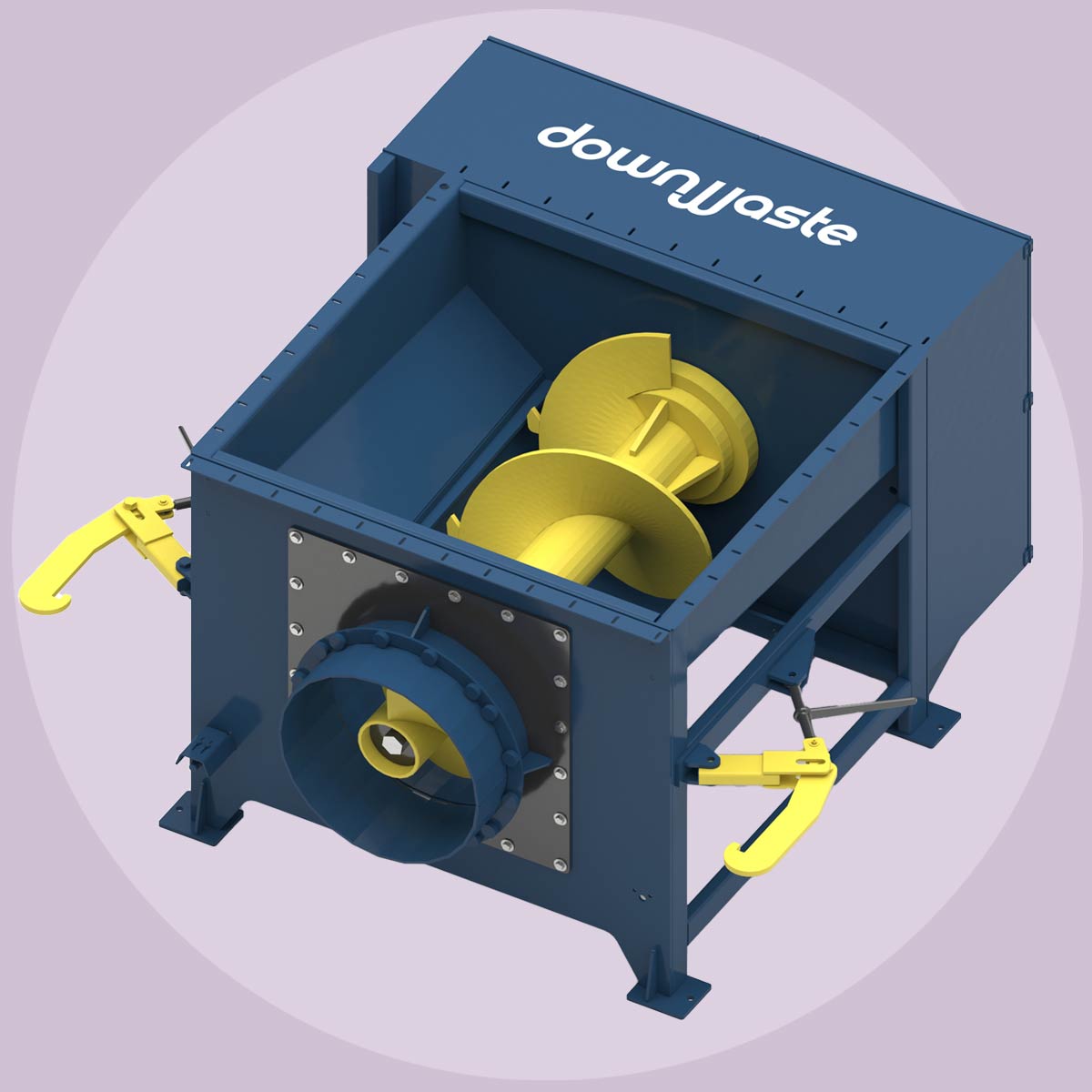

Our Auger Compactor is a cutting-edge solution for efficient and economical waste compaction. With its innovative auger design, this machine shreds and compacts materials, significantly reducing their volume and minimizing disposal costs.

Designed to handle a wide range of materials, from cardboard and plastics to wooden crates, the Auger Compactor is a versatile and reliable choice for businesses of all sizes. Its user-friendly interface and safety features make it easy to operate, ensuring a safe and efficient waste management process.

By investing in an Auger Compactor, you can significantly improve your waste management processes, reduce costs, and contribute to a more sustainable future.

Ideal for businesses and institutions with dedicated waste management areas, the Stationary Auger Compactor offers exceptional efficiency and cost-effectiveness. Its fixed installation provides a reliable and long-lasting solution for high-volume waste compaction needs.

| Model | Drive Power (kW) | Filler Aperture (mm) | Dimensions (L x B x H) (mm) | Height (mm) | Weight (kg) | Electrical |

|---|---|---|---|---|---|---|

| DW-AU.01 | 11.0 | 1400 x 1400 | 1900 x 2050 | 1300 (without hopper) | 2350 | 400V / 50Hz / 32/50/62/80/100A |

| DW-AU.02 | 15.0 | 1400 x 1400 | 1900 x 2050 | 1300 (without hopper) | 2500 | 400V / 50Hz / 32/50/62/80/100A |

| DW-AU.03 | 18.5 | 1400 x 1400 | 1900 x 2050 | 1300 (without hopper) | 2600 | 400V / 50Hz / 32/50/62/80/100A |

| DW-AU.04 | 22.0 | 1400 x 1400 | 1900 x 2050 | 1300 (without hopper) | 2750 | 400V / 50Hz / 32/50/62/80/100A |

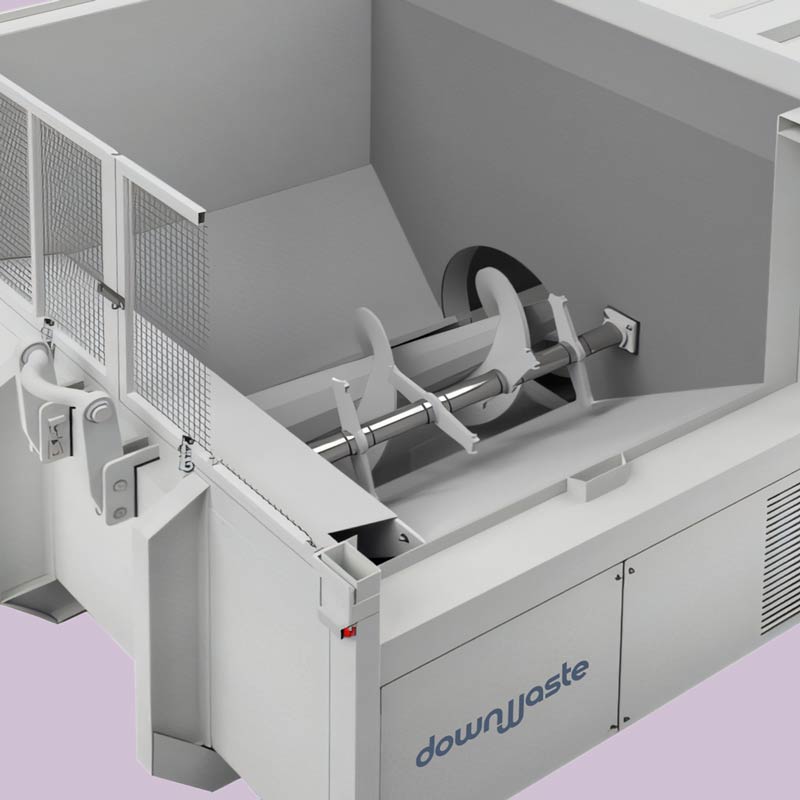

Maximize your operational flexibility with our mobile auger compactors. These self-contained units combine the press and container into a single, portable unit, eliminating the need for fixed installations. Simply position the machine wherever it’s needed on your premises, significantly reducing installation and connection costs.

| Model | Drive Power (kW) | Container Volume (m³) | Dimensions (L x B) (mm) | Height (mm) | Weight (kg) | Filling Height (mm) | Electrical Connection |

|---|---|---|---|---|---|---|---|

| DWAC-18 | 11 | 18 | 6100 x 2470 | 2750 | 4900 |

1580 (without hopper) | 400V / 50Hz / 32A |

| DWAC-20 | 11 | 20 | 6400 x 2470 | 2750 | 5100 | 1580 (without hopper) | 400V / 50Hz / 32A |

| DWAC-22 | 11 | 22 | 6700 x 2470 | 2750 | 5300 | 1580 (without hopper) | 400V / 50Hz / 32A |

| DWAC-25 | 11 | 25 | 7300 x 2470 | 2750 | 5500 | 1580 (without hopper) | 400V / 50Hz / 32A |

Hydraulic based chute fed

automatic compactors

Vertical balers in various sizes

to produce bales from recyclables

Heavy duty waste press compactors for

residential and industrial mega buildings

HDPE wheelie collector bins

available in all industry sizes

2500L and 1100L Heavy Duty

Hot Dip Galvanized Trolleys

Prolitec’s patented malodor

control technology

Sorting tables for your indoor

recycling facility

Using an auger waste compactor offers several benefits for waste management: First, it is Cost Efficiencient: It achieves significant volume reduction of waste and recyclables, leading to lower disposal costs. Second, its Ease of Use: The machine’s design ensures safe and straightforward operation, simplifying tasks for your staff. Third, its Generous Loading Aperture: The large 1400 x 1400 mm opening distinguishes auger compactors from the competition. Fourth, High-Performance Options: Available in power ratings of 11, 15, 18, and 22 kW, providing rapid and effective compaction .Last but not least, its Flexible Integration: Designed to fit flexibly and seamlessly into your building infrastructure, with options for ground, ramp, or through-the-wall filling.

An auger compactor achieves maximum volume reduction through its innovative design which allows Shredding in the Filler Space: The auger shreds material while still in the filler space, ensuring efficient preprocessing before compaction. Then, the powerful screw mechanism applies significant force to compact waste materials tightly in the container. Since the auger breaks down solid objects and compresses waste efficiently, it achievies nearly double the waste volume reduction compared to conventional hydraulic press containers.

An auger compactor can handle a wide range of materials, including:

Auger compactors are available in a range of power ratings varying from 11kW to 22kW to suit different operational needs. These power options ensure uncompromising performance, allowing the compactors to handle various types of waste efficiently.

The innovative auger design enhances compaction efficiency in several ways:

Auger waste compactors are equipped with several safety features to ensure secure operation:

Auger compactor models can be produced in various dimensions and specifications to meet different needs.

Mobile auger compactors enhance operational flexibility by:

Auger compactors have low maintenance requirements due to their robust design:

The automatic feed device works with auger compactors by:

The cost-saving benefits of using auger waste compactors include:

Auger compactors offer several advantages over conventional hydraulic press containers:

FOLLOW US

© 2025 DownWaste