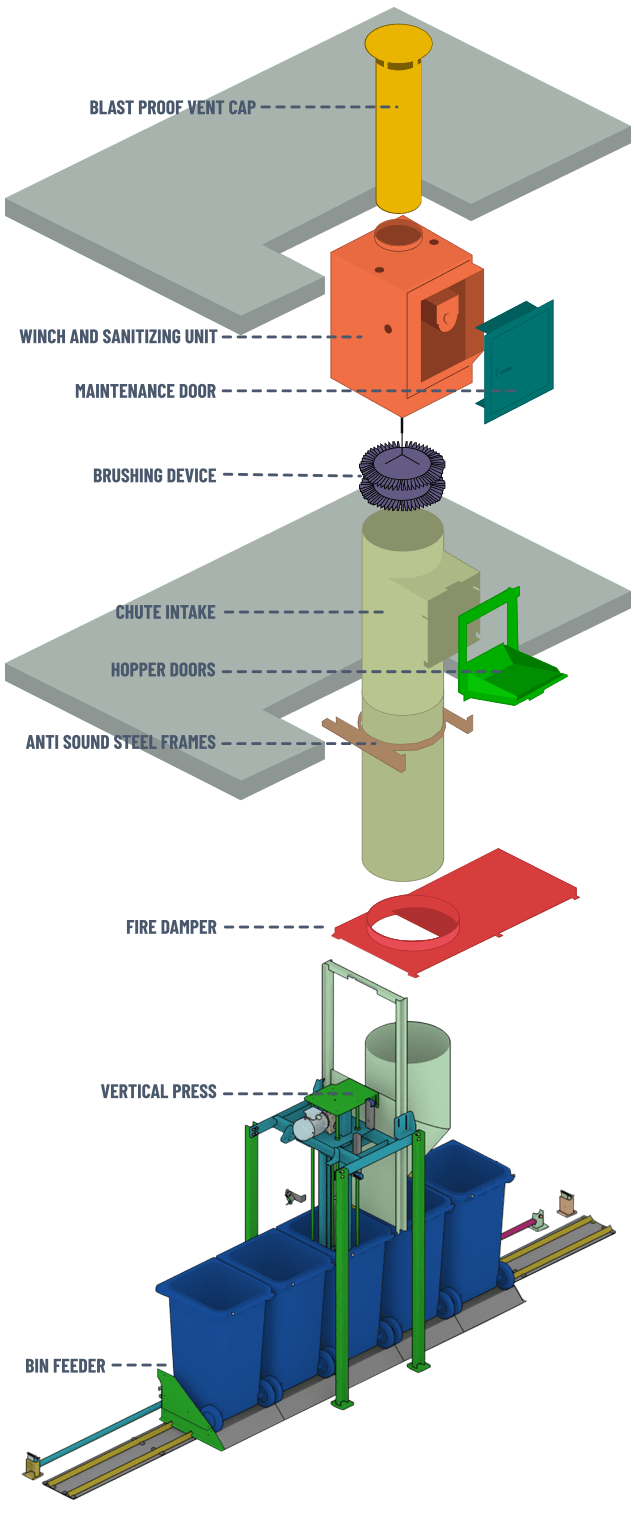

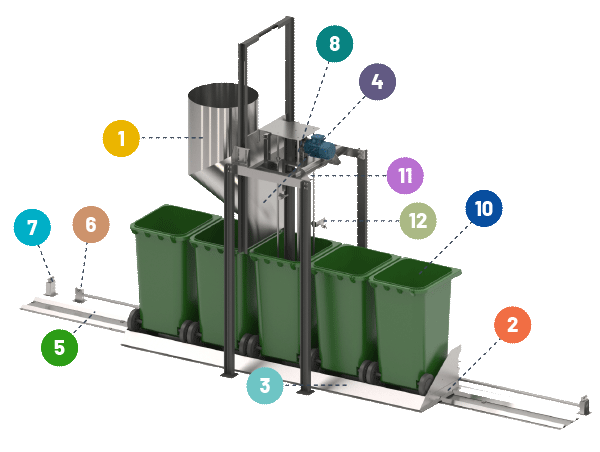

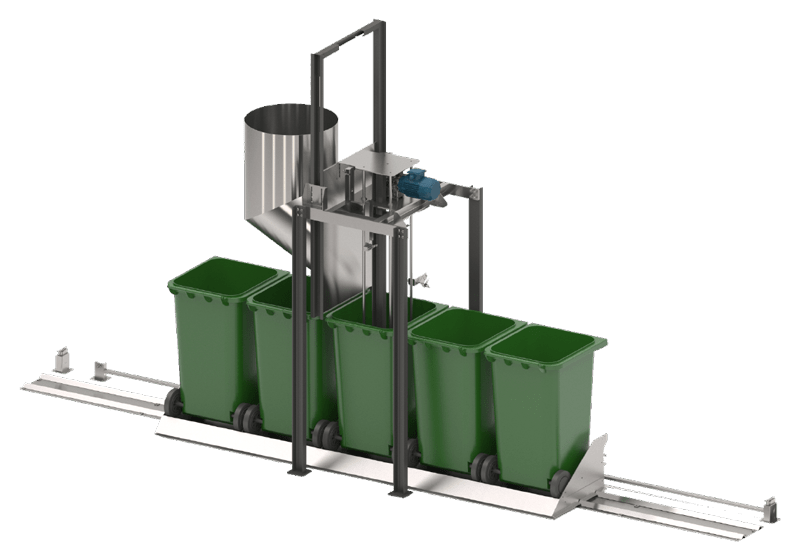

Bin FEED PRESS

The Bin Feed Press is the ultimate solution for reducing frequent waste handling equipment replacements. The automatic operation cycles all waste bins, requiring staff only when bins are fully compacted. This system enhances waste management solutions, optimizing garbage room equipment while minimizing workload and trolley usage.