LAUNDRY CHUTE

Luxury hotels and private villas choose hotel laundry chutes over service elevators for handling bulky laundry from individual floors. We offer a variety of custom laundry chute solutions in steel, designed for quick and easy laundry chute installation, ensuring efficient laundry disposal.

Laundry Chute Systems

Downwaste manufactures seamlessly welded chute trunks that ensure safe and effortless delivery of your sheets and towels to the laundry room.

ENHANCED SOUND PROPERTIES

A quiet laundry chute system for convenience in your building or hotel laundry chute setup. The chute is fixed to floors with hot dip galvanized brackets equipped with anti-vibration rubber pads. All outer surfaces of the chute are coated with sound-dampening material for an efficient laundry disposal solution

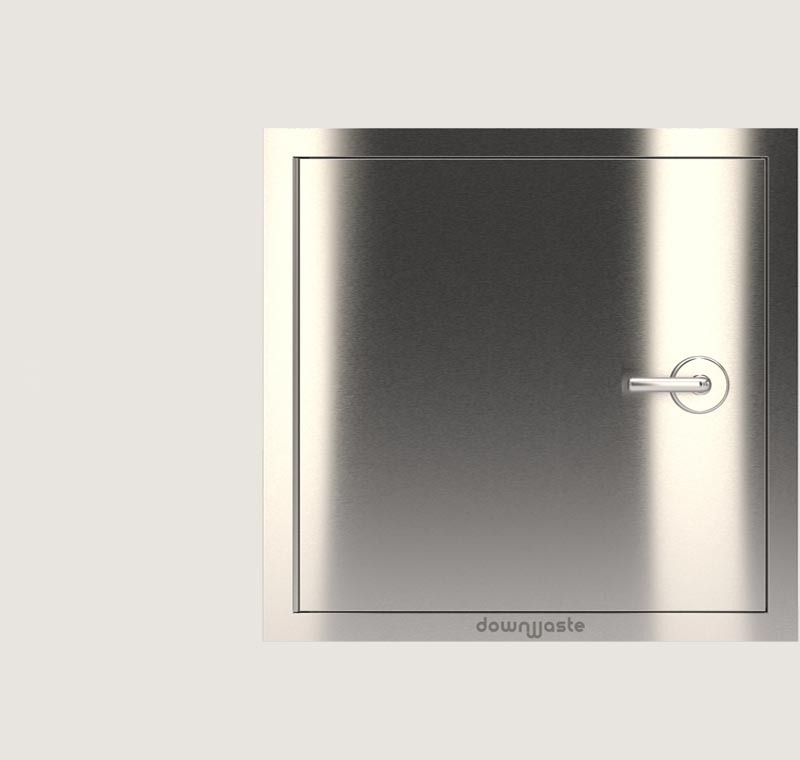

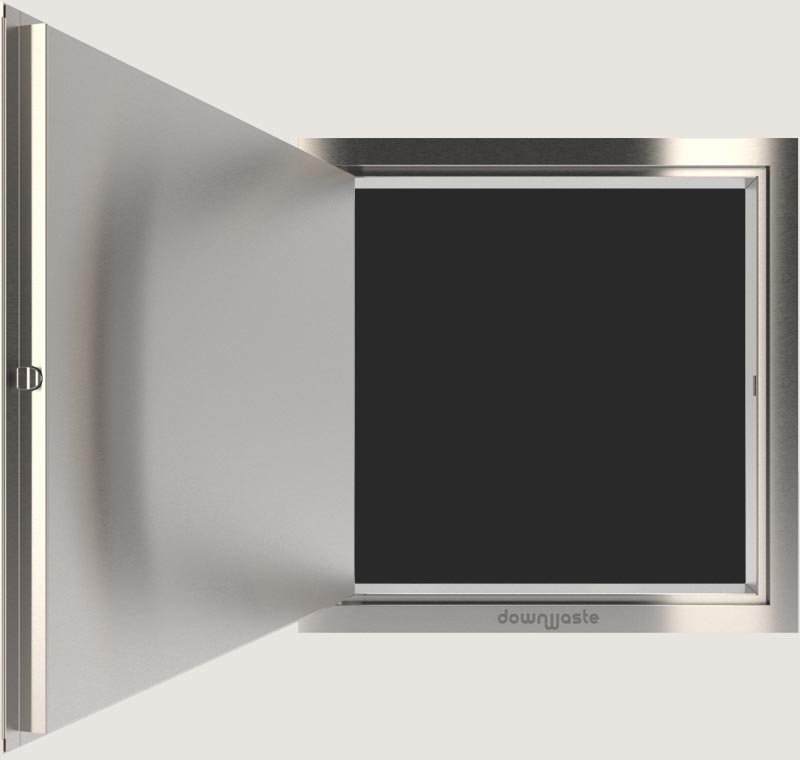

Ergonomic Door Design

Our laundry chute system doors are crafted for ease of use and operational comfort. Choose from fully electrostatic-painted mechanical or stainless-steel interlocking or password access doors in 304 or 316 grade. The heavy-duty, positive-latching handles ensure secure closure with every use, making our laundry chute solutions both reliable and safe.

MORE SAFETY

Our chute doors and dampers are 90-minute Fire Rated according to UL 10B, and 120-minute according to EN1634-1 standard. laundry chute installations are equipped with automatic electric strike locks, ensuring the safety of residents and building operators.

MORE PRODUCTIVITY

Laundry chutes remove the hassle of carrying bulky laundry to the laundry room, reducing the time required for handling the laundry and improving overall efficiency.

Electric Laundry Chute

Our electric laundry chutes are equipped with a 24V electric strike and integrated micro-switch, chute doors provide real-time feedback on their status across multiple floors. This feature enables electric locking of the hopper doors for laundry chute maintenance or interlocking when any door is open.

Advanced Monitoring and Control

This innovative system not only supports centralized monitoring but also ensures operational safety by automatically locking hopper doors during maintenance or when specific conditions, such as fire safety protocols, are triggered. This intelligent design enhances security, reliability, and user convenience in laundry chute systems.

- Ergonomic design with stainless-steel body, door, and handle

- Features 304 or 316 4B finish leaf and frame for durability

- Slow, silent self-closing mechanism with optional keyed handle

- Complies with NFPA and UL 10B fire-rated for 90 minutes, ensuring safety and reliability

AVABILABLE SIZES

12”x12”

(300x300mm)

15”x15”

(395x395mm)

18”x18” (450x450mm)

21”x21”

(530x530mm)

24”x24”

(600x600mm)

Mechanical Laundry Chute

Our mechanical laundry chute systems are the preferred choice for luxury hotels and private villas, prized for their long-term reliability and low maintenance demands. Available in both painted steel and stainless steel, these hotel laundry chutes are designed for quick and effortless laundry chute installation.

ATTENTION TO DETAIL

- Ergonomic and easy-to-operate mechanical laundry chute system.

- Available in electrostatic painted body with a flush keyed lock or stainless steel with keyed handles

- Features self-closing hydraulic spring and 304/316 stainless steel finish options

- Fire-rated for E120 and EI60 (EN1634-1) and 90 minutes (UL 10B), meeting safety standards worldwide.

AVABILABLE SIZES

12”x12”

(300x300mm)

15”x15”

(395x395mm)

18”x18” (450x450mm)

21”x21”

(530x530mm)

24”x24”

(600x600mm)

Password Access Laundry Chute

Our advanced laundry chute solutions are designed to blend seamlessly with the intelligent infrastructure of modern buildings, offering a synergy of safety and sophistication. Recognizing the diverse needs of luxury hotels and private residences, we provide a harmonious combination of mechanical reliability and smart technology in our custom laundry chute solutions.

Secure Access & Operational Excellence

- Password access screen on each laundry chute door for secure and controlled use

- Electric interlock prevents simultaneous door opening for enhanced safety

- Maintains system integrity through secure access features

- Designed to enhance safety and operational excellence for all users

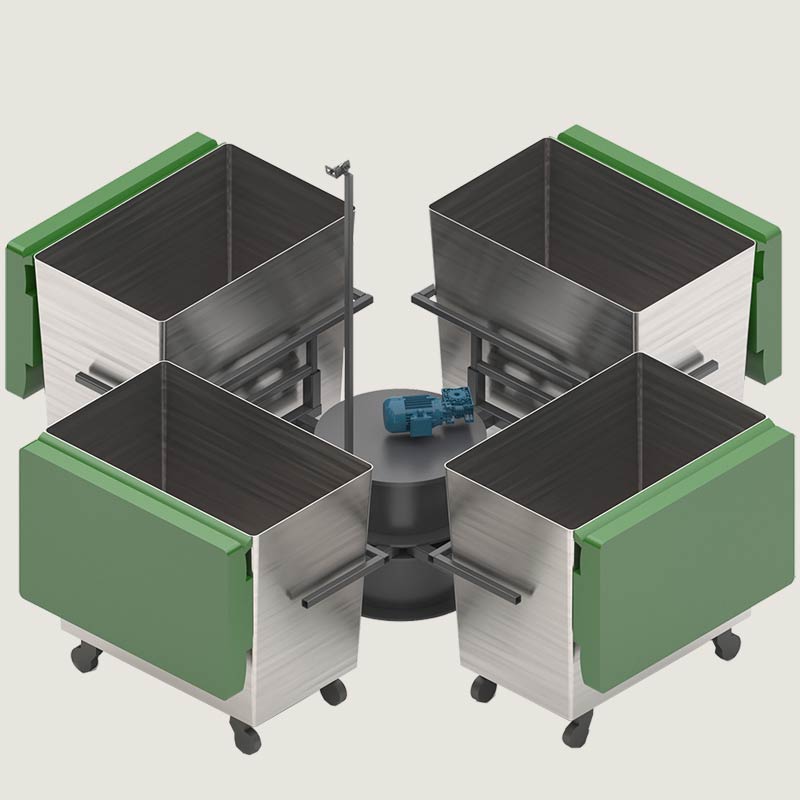

Customized Handling & Disposal

Beyond the laundry chute system itself, we provide a comprehensive range of accessories, including laundry handling tables, rolltainers, and automatic carousels & conveyors, ensuring that the disposal and management of laundry are handled with the utmost efficiency. Our custom laundry chute solutions support efficient, streamlined operations for any facility.

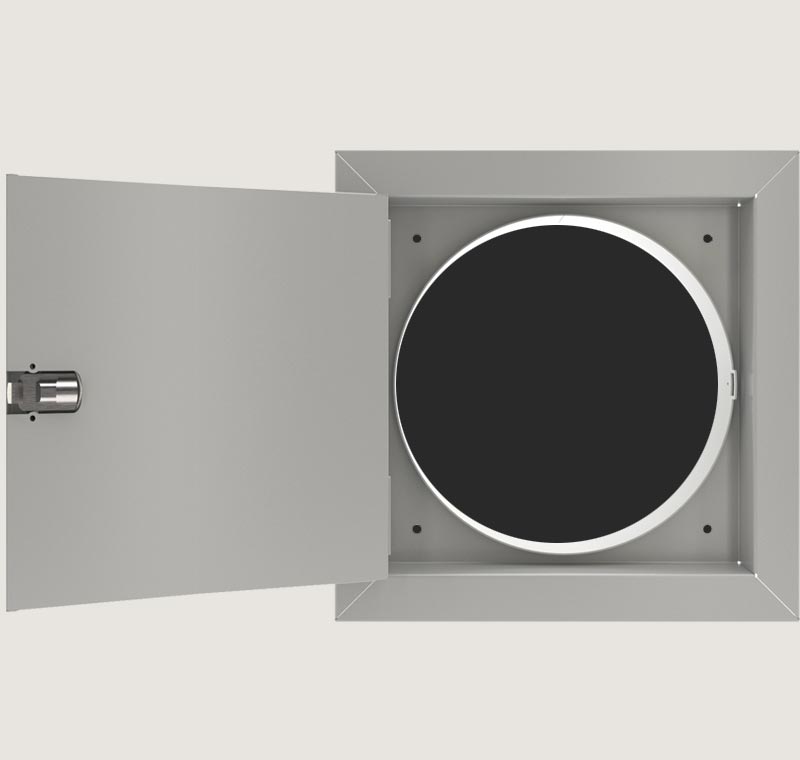

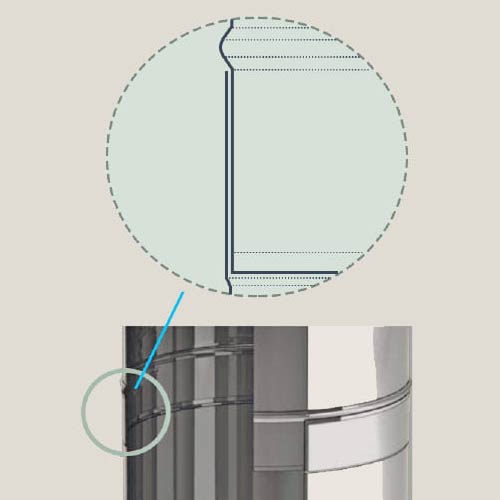

SEAMLESS STRUCTURE

Our continuously welded chutes feature smooth, interlocking male-female connections throughout for a snag-free interior surface. We recommend 600mm diameter, 1.5mm thick S 304 grade stainless steel (standard option) for its superior resistance to alkalis, acids, and humidity commonly found in laundry environments. Other diameters (300mm and 450mm) are also available to perfectly suit your needs.

FIRE SPRINKLERS

Our laundry chute installation includes 1⁄2” Glass Bulb Fire Sprinklers with connector thread, standard response pendant type, and an actuating temperature of 72° C, complying with NFPA 13. Sprinklers are strategically located on alternate floors and at the top of the chute as per NFPA Code 82, ensuring safety throughout the chute system.

LAUNDRY DISCHARGE

Our system allows you to safely and conveniently throw clothes down the chute, where they will land securely in your basket. This mechanism includes a fire-rated, top-hinged stainless steel discharge door held open with a U.L.-approved fusible link set at 72° C, providing both convenience and safety.

Laundry chutes are designed to manage laundry in any multi-story establishment, allowing for quick and easy disposal of laundry by occupants and safe and efficient removal of that laundry via chute by the caretaking staff. DownWaste® chutes are technically superior, clean, quiet, and environmentally conscious solution to laundry disposal.

Hotels, student accommodations, serviced apartments, eldercare units, hospitals can greatly benefit from laundry chutes.

The laundry chutes can be with electric strike doors or completely mechanical doors. While the mechanical doors without the electric controls practically the same, it is not convenient to limit the access to these doors instantly. In other words, laundry chutes with electric strike allows instant locking of the doors at other floors when one doors is opened, when the receptive rolltainer is full, or during electricity cuts or cases of fire.

Electric laundry chute hoppers are equipped with electric strike locks or password-access panels, offering advanced security features. These systems may include instant interlocking doors, integrated with cleaning and discharge sensors, allowing for controlled access via password or card swipe. This prevents unauthorized use and enhances safety. On the other hand, mechanical laundry chute hoppers feature keyed panic bar handles with physical keys, providing a simpler yet effective security measure. In commercial settings like hotels, electric systems are especially valuable for efficiently managing large volumes of laundry.

Handling of bulky laundry can be a challenging task for a hotel or a building. Without a laundry chute, the hard work can be more than just a hassle. Bringing the laundry to the laundry collection room from a service elavator would increase the labor and energy costs dramatically.

Laundry chutes are shaped from stainless steel 304 or 316, with a minimum thickness of 1.5mm, fully factory-assembled and all linear joints are automatic continuous TIG welded. The intake doors are bolted in place on throats formed into the chute. All chute sections shall flash inside the sections below and there are no bolts, clips, or other projections inside the chute to snag the flow of material. Pre-positioned support frames assure proper intake levels and there are no expansion joints in the chute between all support joints. Discharge offsets, where required, are reinforced and separately supported in the impact area.

A clothes chute simplifies the task of moving dirty laundry from upper floors to the laundry room, reducing clutter and saving time. It’s especially useful in multi-story homes, where transporting laundry can be cumbersome.