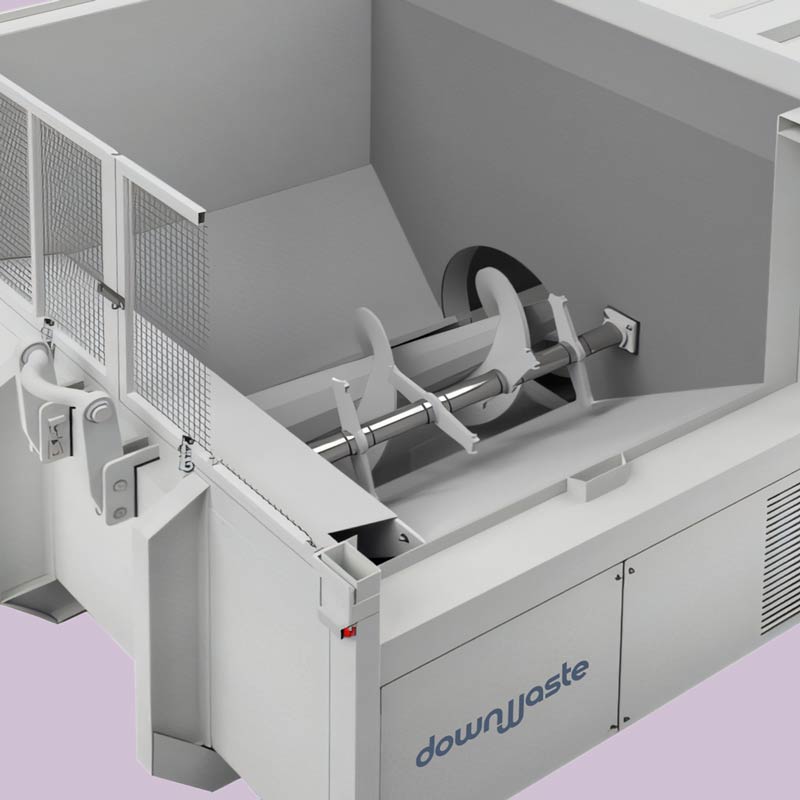

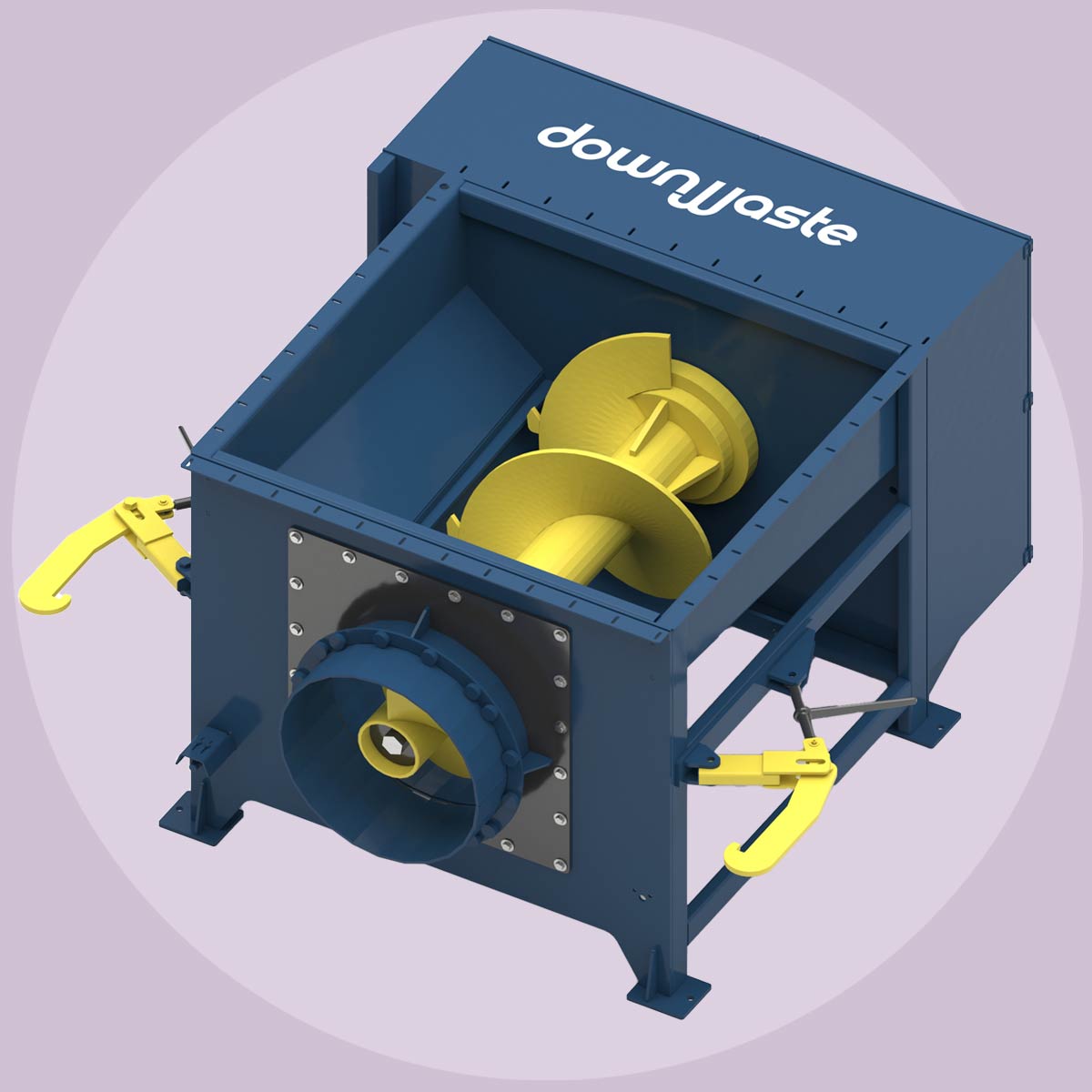

AUGER (SCREW) COMPACTORS

Our auger compactors provide an innovative and economical waste management solution. With an advanced screw-driven design, these continuous waste compactors efficiently shred and compress materials, significantly reducing waste volume while lowering disposal costs.

Designed to handle a variety of waste materials, from cardboard and plastic to wooden crates, our industrial waste compactors are ideal for businesses of all sizes. Equipped with user-friendly controls and built-in safety features, these waste processing compactors ensure seamless and efficient waste management.