PRESS COMPACTORS

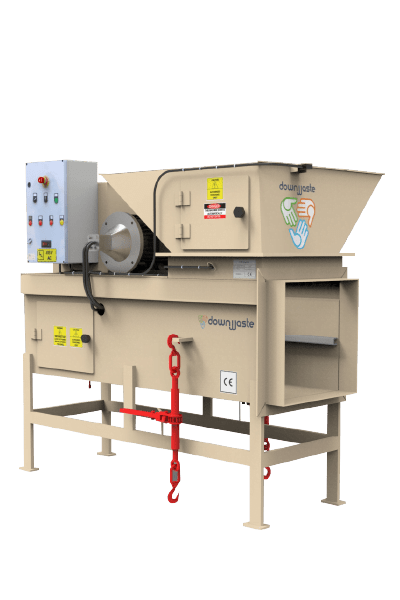

Downwaste deploys heavy duty waste press compactors to residential and industrial mega buildings to minimize the required handling space for the waste by reducing waste fractions to 1/6 of the original volume. These mobile units not only reduce transportation and disposal costs but also they are safe and convenient.

Refuse Press Compactor is the optimum solution for handling large amounts of waste as it is easily and safely compacted in a sealed container, saving space and reducing number of trolleys required to store.

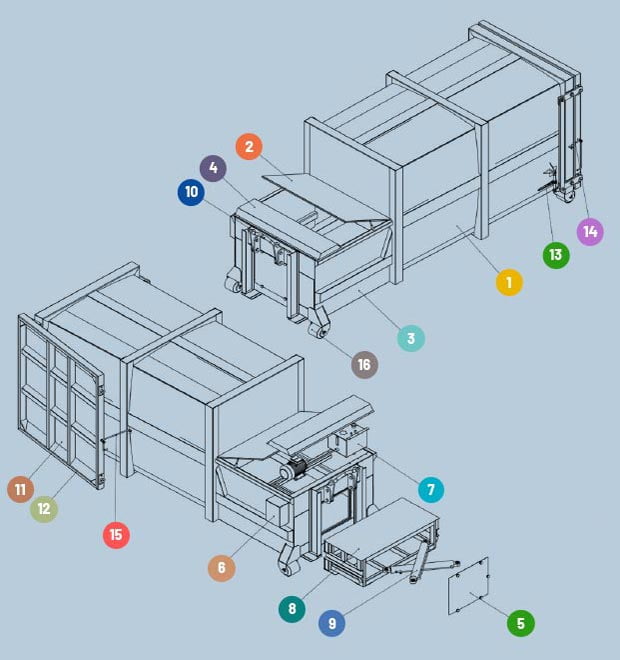

OPTIONS

- Hydraulic opening of discharge door

- Integrated bin lifter to customer specific bins

- Lifting unit at front or side

- Wide range of colour options

FEATURES

- 100% and 80% Full indicator light

- Integrated hook in the front and back

- Automatic, hydraulically controlled lifting and lid opening

- 24V safe and reliable digital control

- Sensors to automatically start the compacting process when the charge box is full

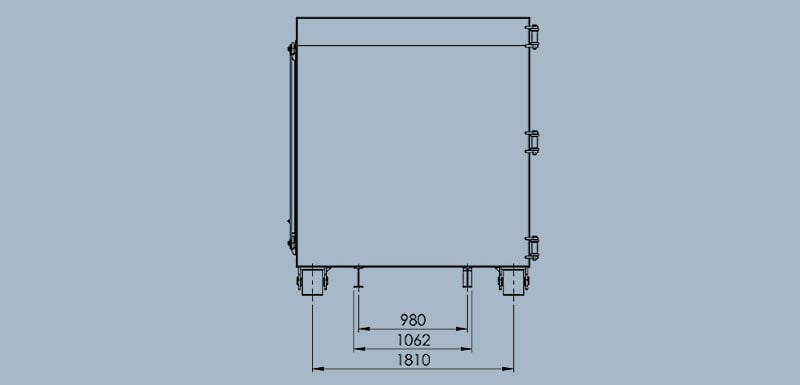

TECHNICAL DATA

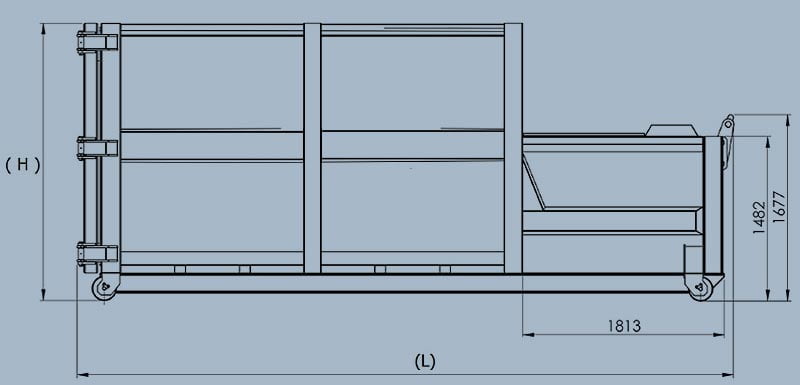

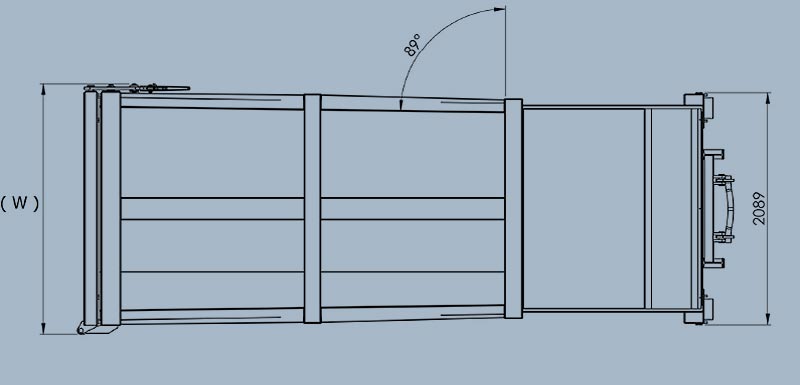

- DWPC 12

- DWPC 16

- DWPC 18

- DWPC 20

- Net capacity12 m³

- (L) Machine length5050 mm

- (W) Machine width2254 mm

- (H) Machine height2497 mm

- Feed-opening length1057 mm

- Feed-opening width1714 mm

- Feeding Hopper Capacity1,3 m³

- Compaction force4:1

- Hydraulic oil tank28 liter

- Electric Motor5,5 kW

- Power supply3 x 400 V, PE/50 Hz

- Net capacity16 m³

- (L) Machine length5425 mm

- (W) Machine width2254 mm

- (H) Machine height2497 mm

- Feed-opening length1057 mm

- Feed-opening width1714 mm

- Feeding Hopper Capacity1,3 m³

- Compaction force4:1

- Hydraulic oil tank28 liter

- Electric Motor5,5 kW

- Power supply3 x 400 V, PE/50 Hz

- Net capacity18 m³

- (L) Machine length5640 mm

- (W) Machine width2254 mm

- (H) Machine height2497 mm

- Feed-opening length1057 mm

- Feed-opening width1714 mm

- Feeding Hopper Capacity1,3 m³

- Compaction force4:1

- Hydraulic oil tank28 liter

- Electric Motor5,5 kW

- Power supply3 x 400 V, PE/50 Hz

- Net capacity20 m³

- (L) Machine length5900 mm

- (W) Machine width2254 mm

- (H) Machine height2497 mm

- Feed-opening length1057 mm

- Feed-opening width1714 mm

- Feeding Hopper Capacity1,3 m³

- Compaction force4:1

- Hydraulic oil tank28 liter

- Electric Motor5,5 kW

- Power supply3 x 400 V, PE/50 Hz

Industrial press compactors are heavy-duty machines designed to minimize waste volume by compressing waste materials to a fraction of their original size. These compactors are deployed in residential and industrial settings to reduce the handling space required for waste, and they are especially effective in high-volume waste environments such as mega buildings

Press compactors are needed by facilities that generate large amounts of waste and require efficient, safe, and sanitary handling of refuse. This includes residential complexes, industrial sites, hospitals, and any establishments looking to reduce the physical footprint of their waste management system

Press compactors work by using hydraulic systems to exert a high level of force on the waste materials, compressing them into smaller, more manageable sizes. This process significantly reduces the volume of waste, making it easier to transport and dispose of. The compactors can automatically start the compaction process when the charge box is full, ensuring maximum efficiency.

Compactors for waste collection are designed to gather and compress waste from various sources, consolidating it into a sealed container. This not only streamlines the collection process but also improves the efficiency of the entire waste management chain by decreasing the space required for storing waste.

Press compactors are important because they effectively manage waste volume, leading to improved sanitation and reduced environmental impact. By compacting waste, they decrease the likelihood of spillage and odors, and they also lower transportation and disposal costs.

The benefits of using press compactors include reducing the volume of waste by up to six times, minimizing the space required for waste handling, and decreasing operational costs. They also enhance safety and convenience in waste management.

DownWaste equipment offers advantages such as the ability to order customer-specific bins and capacities, hydraulic discharge doors for ease of operation, a wide range of container sizes, and color options to suit different settings.

The right press compactor for you depends on the volume of waste you generate, the space available for waste handling, and specific operational requirements. DownWaste offers various models with different capacities ranging from 12 m³ to 20 m³ to accommodate different needs.

Features of using waste press compactors include indicator lights for fullness, large feed openings for easy loading, automatic and hydraulically controlled lifting, and high compaction force. These features ensure efficient and safe operation of the compacting process.

Waste compactors are capable of compressing a wide range of materials, typically those generated in residential and industrial settings, including general waste, mixed recyclables, and potentially bulkier items. The goal is to reduce the volume and prepare the waste for efficient disposal or recycling.

Installation To obtain a quote for press compactors installation, it’s recommended to contact DownWaste with specific details about your waste management needs.